As part of an annual Essential Inspection for one of the largest UK food retail, wholesale and distribution companies our inspectors came up with some great recommendations for any safety officer overseeing forklift operators.

What we did

Our rack safety inspectors undertook the annual inspection of pallet racking according to SEMA guidelines, with particular attention to the inspection of beams, uprights and frame bracing.

They were also on hand to make observations of the forklift operatives and their use of the racking, including 8 lanes of Dexion P90 drive-in racking.

What we found

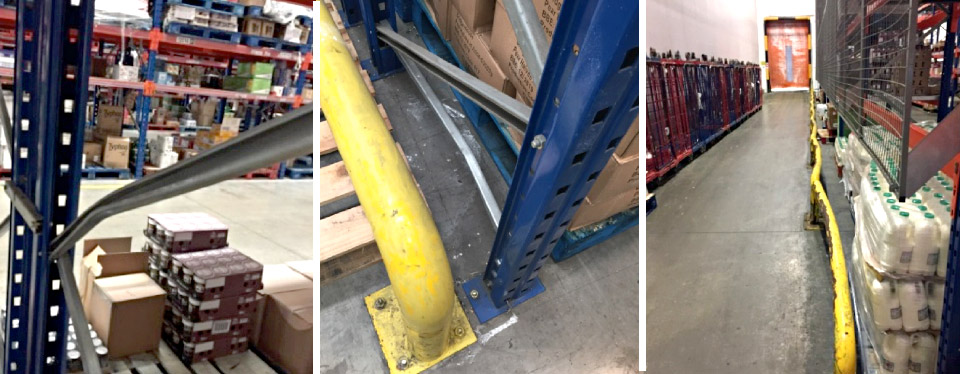

Carried out from the ground floor level, we discovered a number of ‘red risk’ and ‘orange risk’ damaged uprights, horizontal and diagonal bracing bars. For such a large warehouse this is not unusual but we also found a lot of low level ‘nudge’ damage that in isolation would only be recorded as ‘green risk’.

Our inspectors understood that put together this showed a lack of experience from the forklift operators. As pallet racking by it’s nature is made of light materials each small nudge in the racking makes it more unstable and can become a serious and costly problem.

Our Recommendations

As well providing a detailed SEMA racking and shelving survey we recommended that the customer give the drivers guidance on the correct positioning of pallets and the adequate clearances between uprights and pallets.

As part of the same survey we also noted a lot of loose wrapping hanging from pallets into the aisle at high level which has the potential to get tangled with FLT’s and can cause accidents/incidents.

What they did

The customer took the recommendations and are planning to update all training practices and book rack safety awareness training with us.

Get in touch

Want to keep your team safe and racking stable? Get in touch and talk to us about your annual rack inspections and safety awareness training.